Aluminum plastic separating machine

1. Automatic design , simple operation and stable performance; 2. The separation rate can reach to 99%, and the finished product can be sold directly; 3. Dry type separation no waste water discharge, no secondary pollution; 4, Customized design according to customer requests, low power consumption, low noise. 5. Wide range of sorting materials, fast sorting speed;

Description

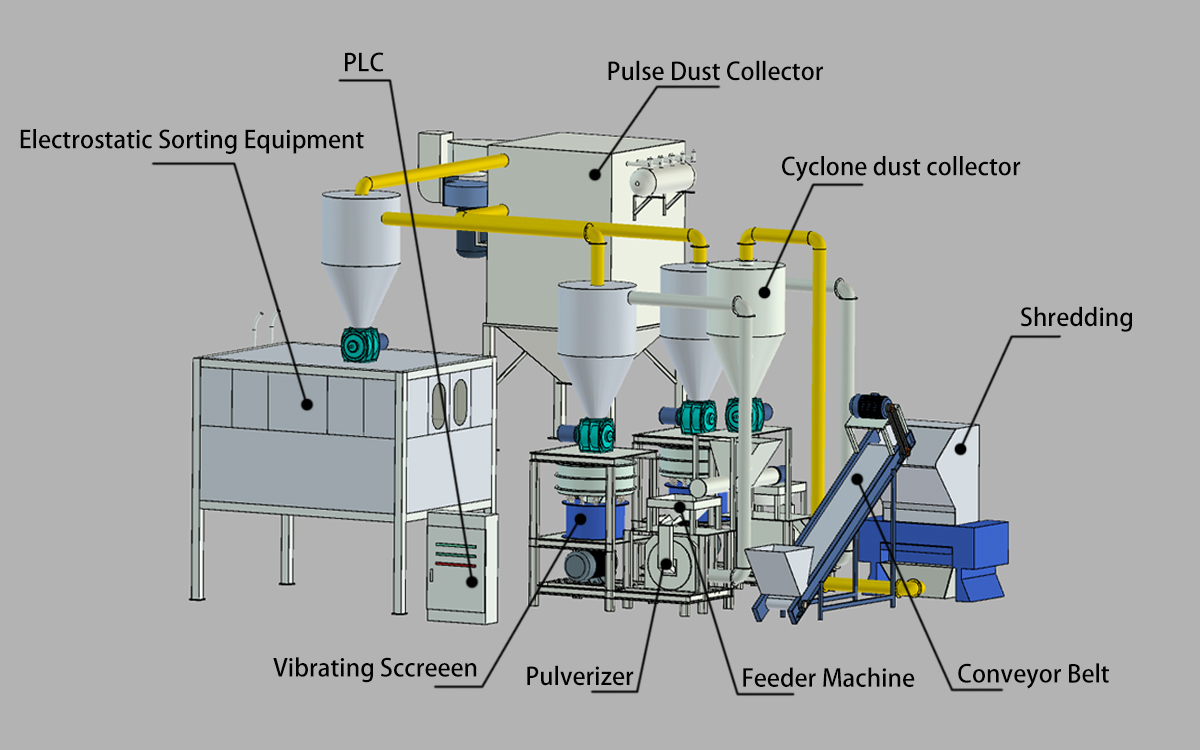

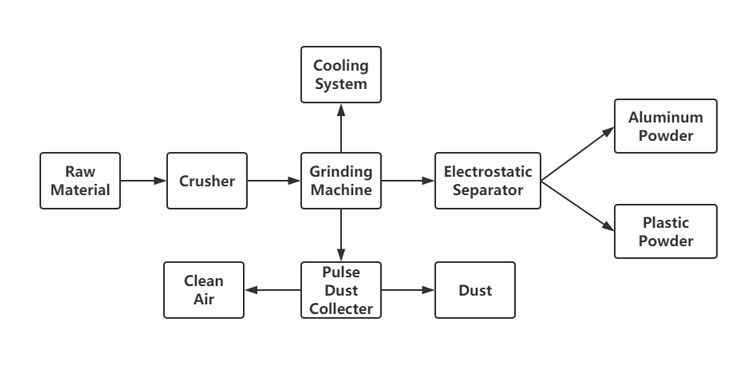

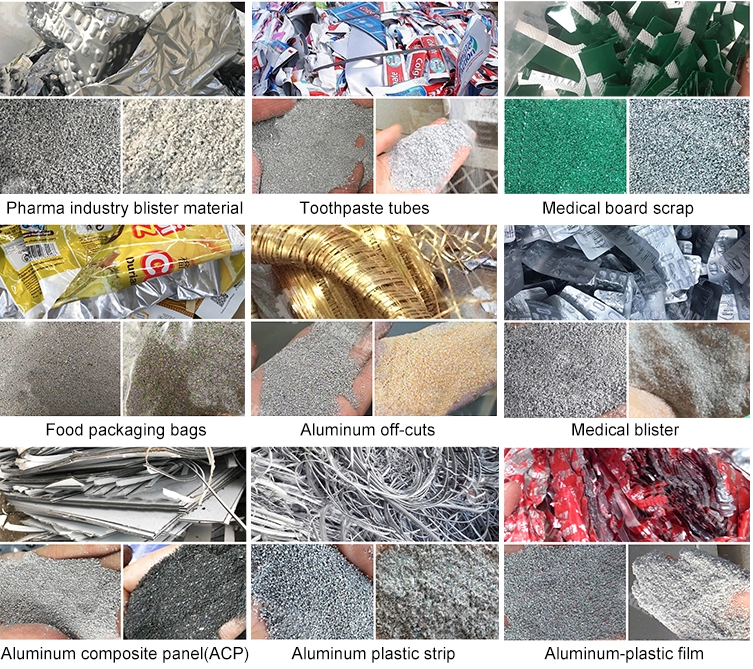

Aluminum plastic separating machine Aluminum plastic separating machine is a production line for crushing and grinding the aluminum and plastic composite materials to recover aluminum and plastic from the scrap aluminum plastic composites materials. It is widely used for recycling all kinds of aluminum and plastic composites such as scrap medical blister, aluminum plastic plate, aluminum plastic foil,toothpaste tubes and aluminum plastic package bags etc. PROCESS DESCRIPTION The aluminum and plastic materials firstly crushed by the knife crusher into 10mm pieces, and then grinding by the water cooling turbo type grinding machine into aluminum and plastic powders. The rotary screen will separate the big size back into the grinding machine and the fine powders will into the electrostatic separator, finally the aluminum and plastic would be separated. The dust collector and cyclone will collect dust make sure workshop clean. Raw Material & Final Product Technical advantages: Customer case

1. Automatic design , simple operation and stable performance;

2. The separation rate can reach to 99%, and the finished product can be sold directly;

3. Dry type separation no waste water discharge, no secondary pollution;

4, Customized design according to customer requests, low power consumption, low noise.

5. Wide range of sorting materials, fast sorting speed;

6. The aluminum plastic separator adopts water-cooling and air-cooling system which make the material separation more purity and high efficiency.