Scrap Copper Cable Wire Recycling Machine

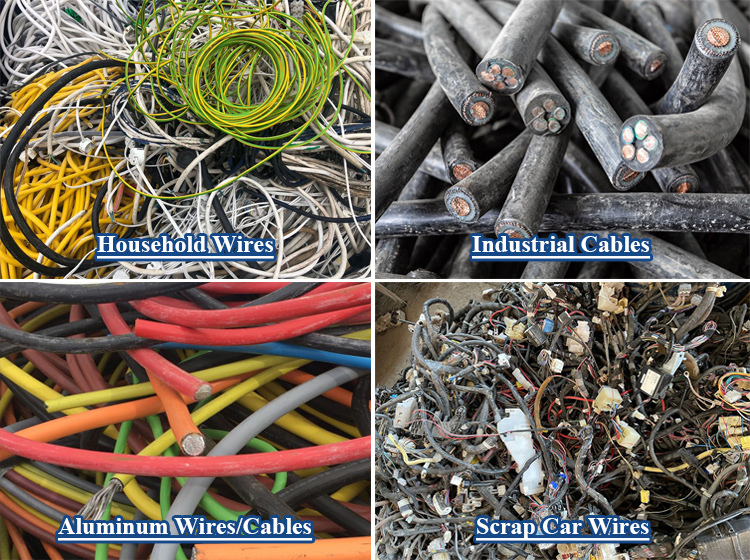

Scrap copper cable wire recycling machine is a production line for shredding or crushing scrap wires and cables into granules and then separate copper or aluminum from plastic. So it is also called copper cable wire granulator, copper and plastic separator.

Description

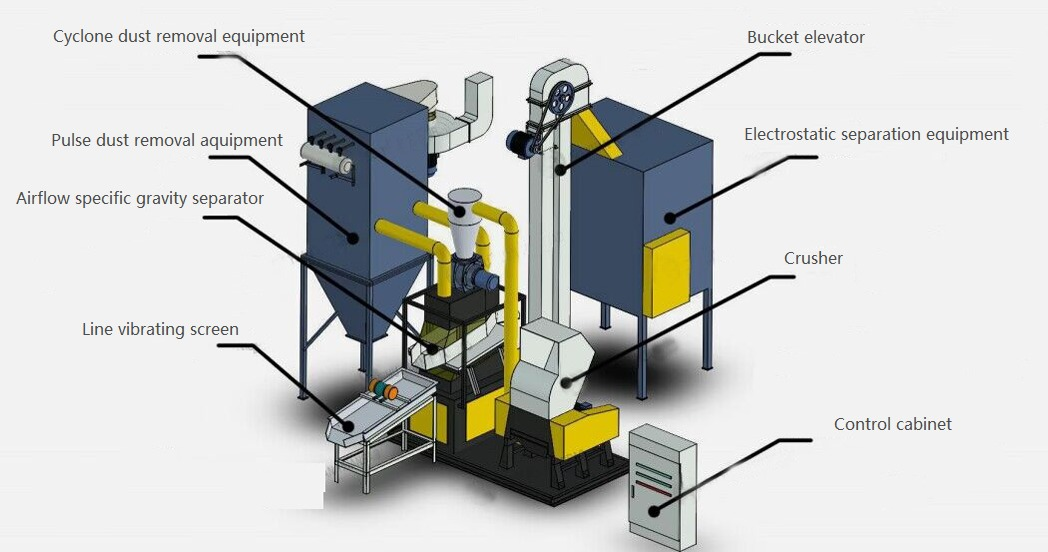

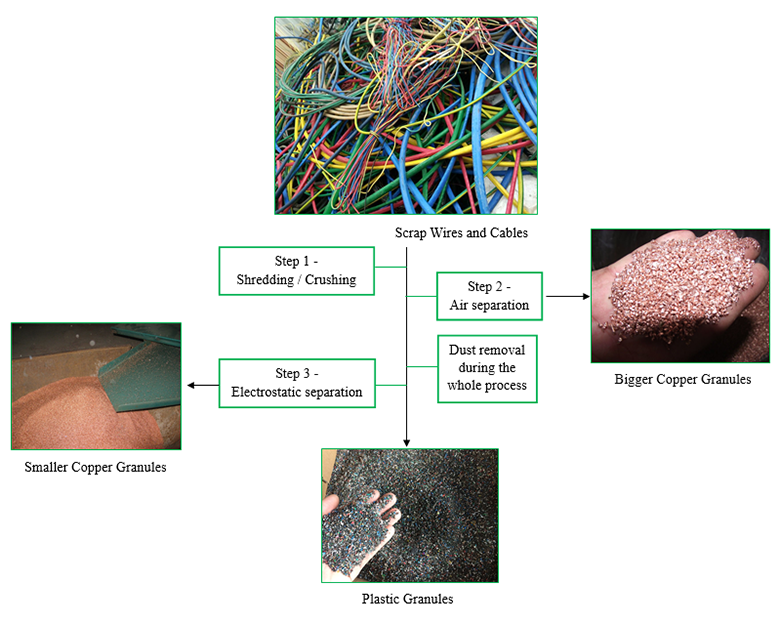

Scrap copper cable wire recycling machine is a production line for shredding or crushing scrap wires and cables into granules and then separate copper or aluminum from plastic. So it is also called copper cable wire granulator, copper and plastic separator. This production line is mainly composed of belt conveyor, shredder,crusher, air separator, electrostatic separator, pulse dust collector,cyclone, etc. Cable granulator can be used for 0.1-50 mm copper and aluminum wire recycling. According to different types of scrap wires and cables, the machine configuration could be adjusted to get the best separaration rate. If you’re not clear about the machine configuration you want, please feel free to contact us to get the customized solution for you. 1) Shredding / Crushing For this type cable granulator machine, scrap wires and cables need to be shredded or crushed into granules at first before separation. If scrap cables are thick and with steel, and also the processing capacity is higher than 500kg/h, usually the shredder is necessary for pre-cutting. If there are mainly thin wires without steel and processing capacity is lower than 500kg/h, then shredder is not necessary. 2) Iron Removal If there is steel or iron mixed with the scrap wires and cables, better remove the steel or iron before crushing process, just in case the crusher blades are easily broken by the steel. For the iron removal, there is automatic magnetic separator is available to use. 3) Air Separation / Electrostatic Separation Air separation is completed by the air separator, by using the principle of density separation. Normally, as the density difference between metal and plastic is big, so it’s easier for them to be separated through air separator. But if there are aluminum wires and cables, or copper wire is very thin, like hair, it would reduce the density difference between metal and plastic, thus cannot ensure the high separation rate. This way, the secondary electrostatic separation is required to reduce the metal loss and increase the separation rate. 4) Dust Removal As scrap wires and cables mainly are dirty, during the shredding, crushing and separation process, so the dust removal system is usually necessary to avoid dust fly around and to keep a clean working environment We can customized different size and capacity machine according to your requirement. Customer case Scrap Copper Cable Wire Recycling Machine

Working Process of Scrap Copper Cable Wire Recycling Machine

Main Features of Scrap Copper Cable Wire Recycling Machine