Silicone Gel Rubber Separator Machine

1. Pure physical sorting, without any pollution, equipment energy consumption and operation cost are low. 2. PLC control and core components of the equipment adopts imported brands. 3. The inner part which touch with the material adopts stainless steel and chrome plating, which increases the sorting accuracy and prolongs the service life of the equipment.

Description

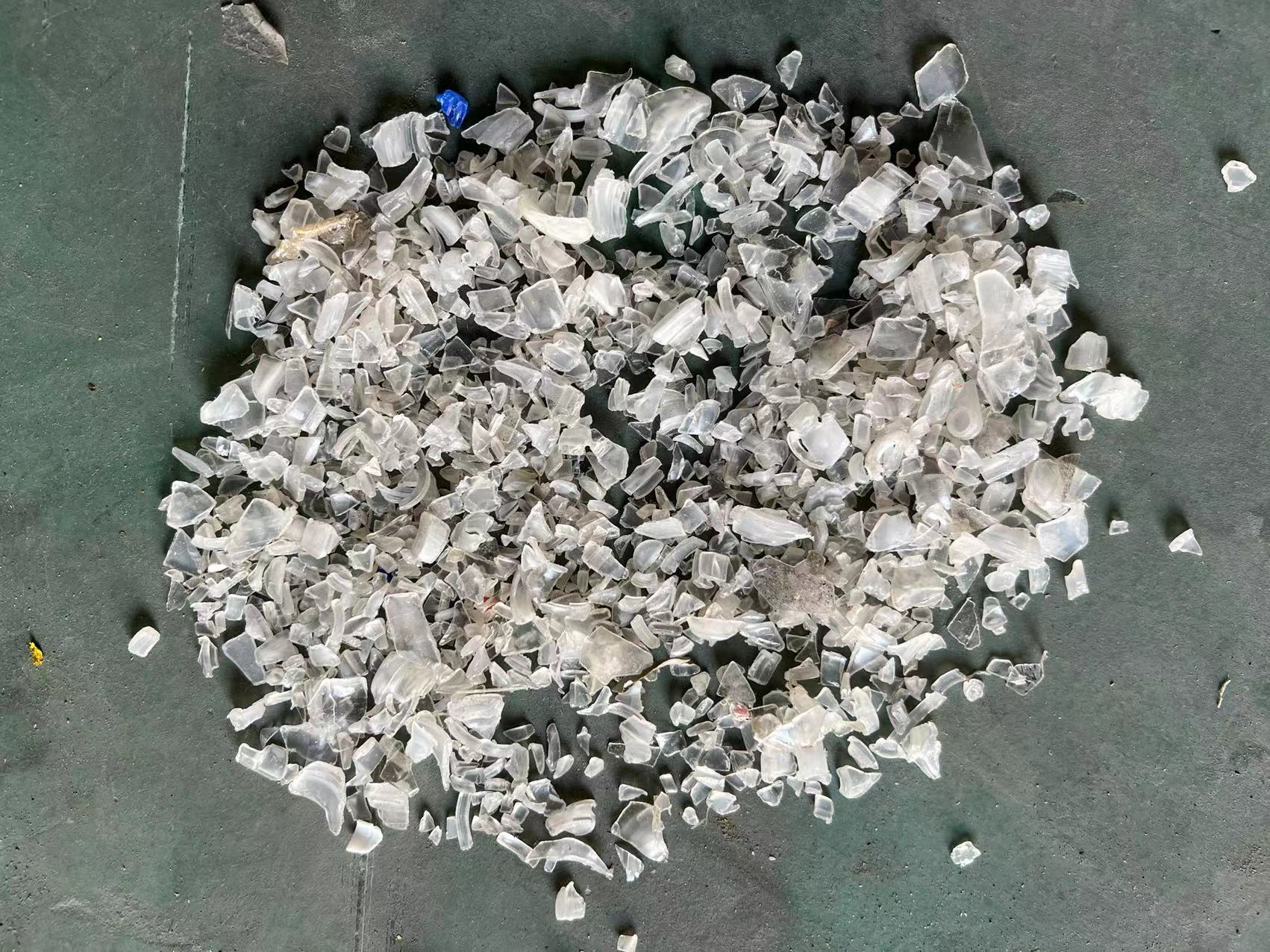

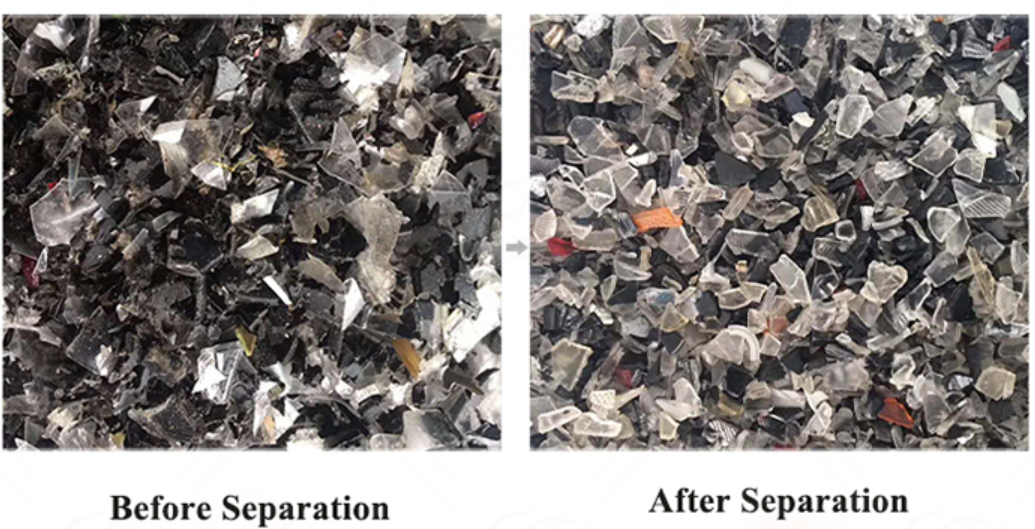

Rubber Silicon Separation Machine by using the different elasticity between rubber or silicone and plastic to separate rubber or silicone from plastic.It is mainly used for sorting silica gel, rubber and plastic in the mixed plastics after the crushing of waste household appliances plastics and other plastics, PP plastic and silica gel in medical infusion bottle and infusion bag, waste battery jar and silica gel plug after breaking, plastics and silica gel in electrical broken materials. Crushed medical waste infusion bottle After separated Household appliance crushed : Main Feature: 1. Pure physical sorting, without any pollution, equipment energy consumption and operation cost are low. 2. PLC control and core components of the equipment adopts imported brands. 3. The inner part which touch with the material adopts stainless steel and chrome plating, which increases the sorting accuracy and prolongs the service life of the equipment. 4. By using the principles of mirror friction and bouncing, the plastics, silica gel and rubber are accurately separated, and the highest separation purity can reach more than 99%. 5. The equipment is equipped with adjustable automatic feeding system, material lifting system, sorting system, automatic feeding and finished material discharging system. It can be operated by one person. Certificates: Silicone Gel Rubber Separator Machine